Exhaust gas systems, in general

Exhaust gas systems are critical in the design of any vessel or land application. They can affect everything from noise and vibrations to engine emissions.

For the so-called "Water Cooled" exhaust systems, design criteria aspects are even more challenging, like securing the waterproof integrity of the hull or a maximum temperature in the engine room to ensure crew safety.

All these demands create a challenging set of design aspects for Discom. Heat reduction in the engine room. A minimal infrared signature. All-round view from the bridge. Discom has been designing, building and supplying water-cooled exhaust gas systems that meet all these requirements and expectations for over 25 years.

Demanding vessels

Naval vessels, merchant ships, workboats, cruise ships and ferries have the most advanced techniques and technologies on board for their designed purposes. That is precisely why these demanding vessels are being equipped with water-cooled exhaust gas systems. Such a system must effectively deal with excess heat, noise, vibrations and harmful substances.

Noise reduction, emission reduction and heat recovery go hand in hand at Discom. By combining these three areas of expertise with our extensive know-how in the field of exhaust gas systems, we design optimally profitable solutions for all these demanding vessels or land applications.

A smaller infrared signature for Navy vessels

The smallest possible infrared signature and minimal noise production are of great importance for navy vessels. Discom developed relatively simple methods to reduce the engine's noise and cool the exhaust gases using direct water injection in the exhaust system. Cooling exhaust gases suppresses the infrared signature and reduces the visibility of the ship to detection equipment.

To meet the diverse wishes of the different Navies, we can produce our solutions in various high-quality materials such as Inconel 625 and titanium. Contact us for more information about all the possibilities.

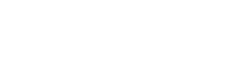

Example of a water-cooled exhaust system with an underwater outlet and above-water bypass

discharged through the ship's hull. This high-end valve is the result of Dutch ingenuity and Discom manufacturing.

Increased comfort for cruise ship passengers

Cruise vessels

Aboard cruise ships, the safety and comfort of guests is of great importance. By choosing a water-cooled exhaust gas system in combination with an emission reduction system from Discom, you increase the comfort of your guests. The exhaust gases are cooled back and blown into the stern wake so they do not rise to the passenger and recreational decks.

In addition, with such a Discom solution, you can ensure that your ship complies with the Stage V standard. This is no mere luxury, as inner cities increasingly focus on reducing emissions. Whatever combination you choose, we ensure the system suits the available space. Even if you opt for a combination with a De-NOx installation to limit your NOx emissions, we know how to fit the system 1-on-1 into the existing engine room situation.

Completely wet or combination dry/wet?

If you opt for a water-cooled exhaust gas system, you have two options: completely wet or a combined dry/wet system.

Completely wet

When utilising a fully wet system, water is injected into the exhaust system as soon as possible following the engine. The exhaust gases are cooled, and most sound attenuation is obtained by passing the mixture through a water lift or a water separator.

Combined dry/wet system

If a water lift/separator causes too much back pressure or the spatial layout does not allow for a completely wet system, you can opt for a combined dry/wet system. In this system, the exhaust gases are initially fed uncooled by a dry – often a combined resonance/absorption – silencer. After this, water is injected to cool the gases. It is possible to install a water separator again after the water injection.

Exhaust opening above or below the waterline?

The position of the exhaust opening affects the acoustic and pressure drop performance of the exhaust system. You can choose to place it below or above the waterline.

Above the waterline

Exhaust gases are carried out through the hull and above the waterline. If you choose to separate the exhaust gases from the cooling water with a separator, you will prevent noise from the falling cooling water and soot traces on the water's surface.

Below the waterline

The exhaust gas is carried out underwater through the hull. The extra transition between water and air creates an excellent attenuation of the exhaust sound. The exhaust gas makes noise in the water at a low sailing speed, and the back pressure quickly becomes too high. That is why we usually apply this option to fast-sailing ships.

Less exhaust gas annoyance for

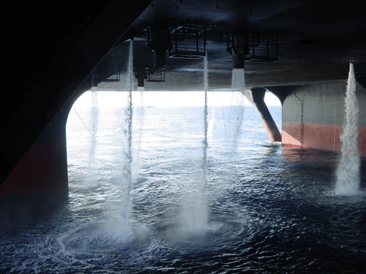

Vessels with dynamic positioning

An important design objective for exhaust systems on ships with dynamic positioning (and no or low sailing speeds) is to avoid exhaust annoyance for the crew, which can cause headaches, nausea and respiratory irritation. Discom has designed several systems for these types of vessels. This objective was achieved by installing diesel oxidation catalysts and by applying exhaust gas cooling through seawater injection. Cooling the exhaust gas increases its density, making it less likely to rise to the upper decks and reducing crew inconvenience. In addition, (some of) the soot present will be washed away with the seawater.

Crane vessel with water-cooled exhausts

The Discom Effect

With your wishes as a starting point, our experienced engineers design a complete water-cooled exhaust gas system that meets all requirements, standards and specifications: that is the Discom Effect. No matter the task complexity, we deliver a reliable total solution.

3D STP file

If you work with Distom, you will receive a 3D STP file for your system that you can fit into your own 3D model. If adjustments are needed, an analysis of the consequences for the system is easy to make, and the necessary changes can be implemented quickly.

Extensive documentation set

In particular, the delivery of military ships involves many administrative actions. Discom provides an extensive documentation set for each water-cooled exhaust gas system. This includes, for example:

- The design drawings,

- The FAT (Factory Acceptance Test),

- The HAT (Harbor Acceptance Test),

- The SAT (Sea Acceptance Test),

Discom: The sustainable all-around specialist

At Discom - the sustainable all-around specialist in exhaust gas systems for the international maritime, industrial and energy sectors - we like to anticipate the standards. Our engineers are experts in the field of noise reduction, emission reduction and heat recovery. We deliver custom solutions as well. Total solutions include silencer, suspension, expansion joints and possibly emission reduction, whether or not combined with heat recovery.